Kairos3D: Tailor-Made Digital Twins for Oil & Gas

Digitalisation is on its way and digital twins are here to assist companies to enter the 4.0 era. The Italian company Kairos3D has developed a specialised software platform for digital twins especially useful for the oil and gas industry. Al Mazroui Engineering, a company of the Al Mazroui Group, brings this state-of-the-art technology to the UAE.

According to a 2019 survey, 90% of industry leaders agree digital transformation will accelerate their ability to achieve operational excellence as a sustainable way of doing business. More particularly, 70% of the professionals surveyed believe digital twins are the right technology to simulate what-if scenarios for better planning and informed decision-making. Petrotechnics, now a Sphera company, collected responses from a broad representation of functions across the hazardous industries, including oil, gas, chemicals and engineering. 29% of the respondents were based in the Middle East.

Paul Marushka, President and CEO at Sphera, commented, “As the third-annual Operational Excellence Index shows, digital transformation is upon us. As companies look for new ways to keep their people safe, their operations productive and their products sustainable, being able to tap into and monitor data from Industry 4.0 solutions will be a major differentiator for organisations looking to separate themselves from the competition.”

What Is a Digital Twin?

A digital twin is a 360-degree virtual replica of an existing physical entity. By bridging the physical and the digital worlds, data is transmitted seamlessly. This allows the virtual entity to exist simultaneously with the physical one. An efficient two-way communication becomes thus possible between physical and virtual worlds.

Digital twins enable companies to optimise operating processes and improve capital investments in the virtual world before applying them in the real one. Wassim Ghadban, Global Director, Innovation & Intelligence at SNC-Lavalin explained in OilandGasMiddleEast.com that: “digital twins can be used to simulate ‘what-if’ or ‘what-will’ scenarios to ultimately raise asset productivity, reliability and performance.”

On a maintenance level, digital twins can help detect early signs of equipment failure or degradation. This way, companies can be proactive and implement corrective maintenance actions before failure occurs and often at a much lower cost.

A Decisive Asset for the Oil & Gas Industry

Industries professionals are using digital twins to improve decision-making by simulating how different factors will respond to the operational reality of an asset before physically duplicating it.

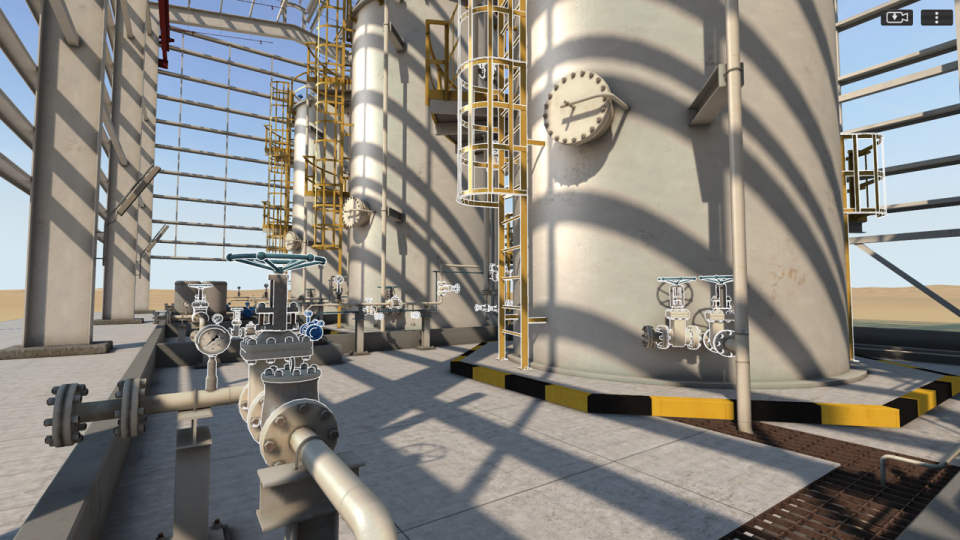

Kairos3D is a cutting-edge real-time 3D development company based in Torino, Italy. With the vision that a step toward the Industry 4.0 is necessary, as digitalisation changes everything globally, its team has developed Gilgamesh: a real-time 3D proprietary software platform. This innovative software offers interactive and immersive 3D CAD (computer-aided design) mobile solutions to assist construction, pre-commissioning, operations and maintenance. It also allows low cost simulations of operations through virtual reality for industrial operators, immersive product experiences for brand innovation and high-fidelity simulators for education and research.

Always looking for innovative solutions for the Emirati market, Al Mazroui Engineering brings the Italian brand’s solutions to the UAE.

Digital twins are crucial assets in achieving operational excellence in the oil and gas industry. With the 3D experiences offered by Gilgamesh, Kairos3D allows its customers to stay ahead of the competition by becoming 4.0 digital companies. ADNOC, Khalifa University, ENI and BP (British Petroleum) have already chosen Kairos3D.

According to a 2019 survey, 90% of industry leaders agree digital transformation will accelerate their ability to achieve operational excellence as a sustainable way of doing business. More particularly, 70% of the professionals surveyed believe digital twins are the right technology to simulate what-if scenarios for better planning and informed decision-making. Petrotechnics, now a Sphera company, collected responses from a broad representation of functions across the hazardous industries, including oil, gas, chemicals and engineering. 29% of the respondents were based in the Middle East.

Paul Marushka, President and CEO at Sphera, commented, “As the third-annual Operational Excellence Index shows, digital transformation is upon us. As companies look for new ways to keep their people safe, their operations productive and their products sustainable, being able to tap into and monitor data from Industry 4.0 solutions will be a major differentiator for organisations looking to separate themselves from the competition.”

What Is a Digital Twin?

A digital twin is a 360-degree virtual replica of an existing physical entity. By bridging the physical and the digital worlds, data is transmitted seamlessly. This allows the virtual entity to exist simultaneously with the physical one. An efficient two-way communication becomes thus possible between physical and virtual worlds.

Digital twins enable companies to optimise operating processes and improve capital investments in the virtual world before applying them in the real one. Wassim Ghadban, Global Director, Innovation & Intelligence at SNC-Lavalin explained in OilandGasMiddleEast.com that: “digital twins can be used to simulate ‘what-if’ or ‘what-will’ scenarios to ultimately raise asset productivity, reliability and performance.”

On a maintenance level, digital twins can help detect early signs of equipment failure or degradation. This way, companies can be proactive and implement corrective maintenance actions before failure occurs and often at a much lower cost.

A Decisive Asset for the Oil & Gas Industry

Industries professionals are using digital twins to improve decision-making by simulating how different factors will respond to the operational reality of an asset before physically duplicating it.

Kairos3D is a cutting-edge real-time 3D development company based in Torino, Italy. With the vision that a step toward the Industry 4.0 is necessary, as digitalisation changes everything globally, its team has developed Gilgamesh: a real-time 3D proprietary software platform. This innovative software offers interactive and immersive 3D CAD (computer-aided design) mobile solutions to assist construction, pre-commissioning, operations and maintenance. It also allows low cost simulations of operations through virtual reality for industrial operators, immersive product experiences for brand innovation and high-fidelity simulators for education and research.

Always looking for innovative solutions for the Emirati market, Al Mazroui Engineering brings the Italian brand’s solutions to the UAE.

Digital twins are crucial assets in achieving operational excellence in the oil and gas industry. With the 3D experiences offered by Gilgamesh, Kairos3D allows its customers to stay ahead of the competition by becoming 4.0 digital companies. ADNOC, Khalifa University, ENI and BP (British Petroleum) have already chosen Kairos3D.

Recent Articles